Our Technical Specialists have the experience and know-how to repair and clean all brands of gasketed plate heat exchangers. Manufacturer repair and maintenance is offered for all gasketed, welded exchangers, and shell and tube exchangers returning units to OEM condition and efficiency.

Field Service

To keep your equipment running in top operating condition, maintenance is essential. We offer comprehensive onsite services to avoid unplanned shutdowns. We respond quickly to emergency situations and offer service outside regular business hours when needed.

Because down time can have a serious financial impact on production, our expert team can diagnosis and trouble shoot problems in the field, thus reducing your down time and financialimpact. To take advantage of our expertise, you can call on our highly qualified service engineers to help onsite and advise you at your facility.

We also offer training to your staff to handle your routine maintenance. This can save valuable time and money on maintenance. We give your staff the expertise to respond quickly and properly maintain equipment, reducing shutdown time.

Reconditioning

We deliver high efficiency and optimal performance by providing service to all brands of heat exchangers for both plate and frame services. This enables you to get all spare parts and reconditioning services for all makes of plate heat exchangers from a single, OEM factory. In addition to plate and frame, we also recondition shell and tube heat exchangers and other equipment. Contact us with your needs.

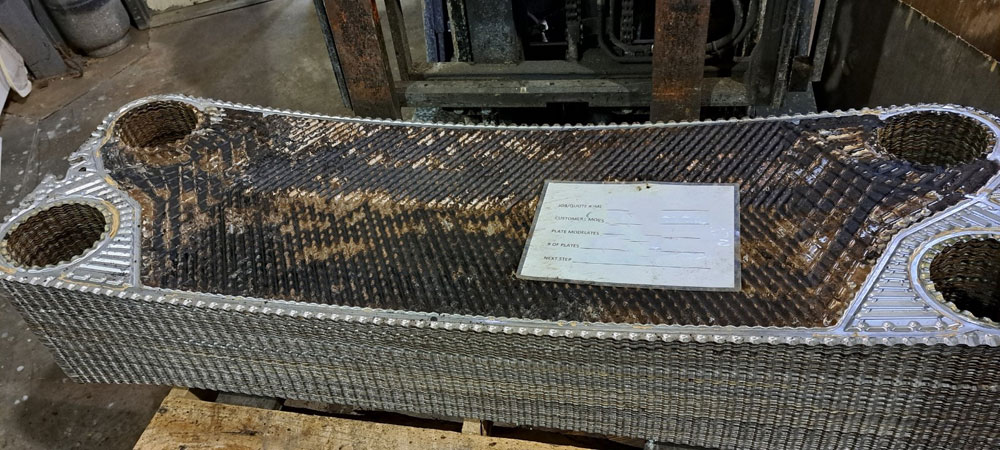

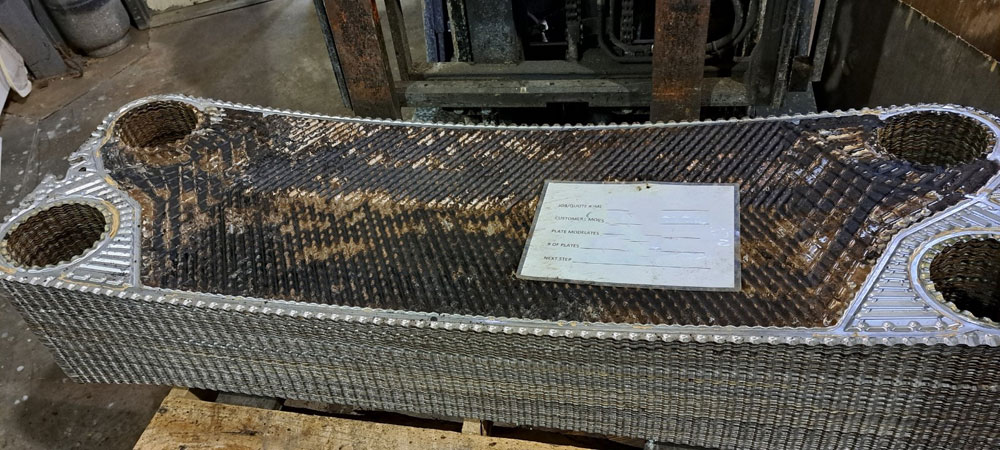

If plate heat exchanger performance lags, it is possible to improve performance through reconditioning. Reconditioning services include:

- Disassembly and visual inspection to determine components that can be reconditioned and those that need replacement

- Removal of glued gaskets, usually with the use of special nitrogen de-bonding systems

- Plate cleaning

- Dye-penetrant testing, if required, to verify plate pack integrity

- Preparation and application of new gaskets to the plates according to updated material specifications

- Reassembly and pressure testing, if desired

Before & After

Repair

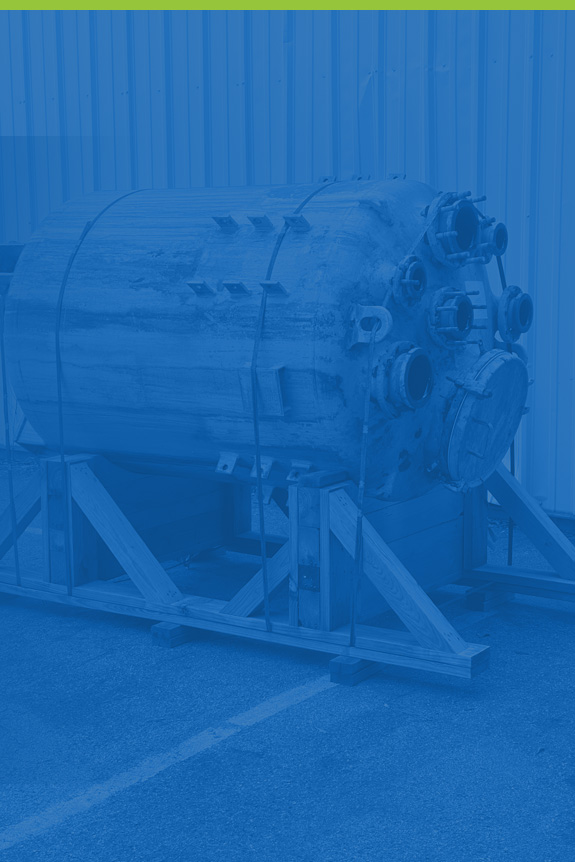

We offer high quality inspections and repair for a variety of equipment, including but not limited to, heat exchangers, decanters, glass-lined equipment and rotary cleaning systems. Our repair services are available both off and onsite, with complete diagnosis and documentation to allow you to make informed decisions. We also provide expedited emergency services based on capacity.

Repairing decanter and disc stack separators

When rotating equipment requires repair, we can provide the following services for our decanters and disc stack separators:

- Welding of areas damaged due to mechanical, chemical or erosion attacks

- Refitting of wear parts, such as o-rings and gaskets

- Replacing worn out or damaged items

- Executing upgrades

- Balancing static and/or dynamic equipment based on needs and available equipment

- Conducting a test run, depending on the equipment

Before & After