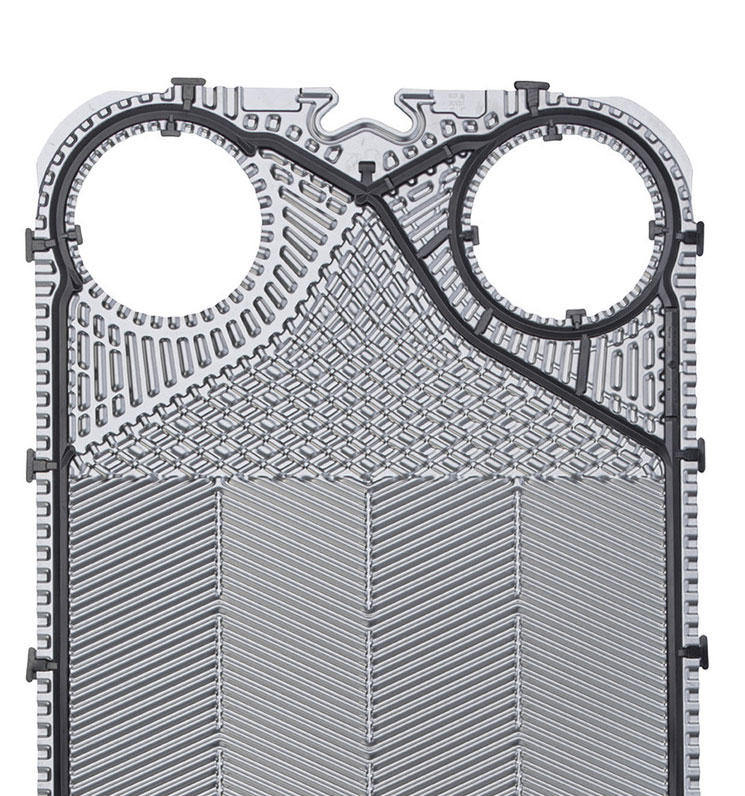

The conventional type of Alfa Laval plate heat exchangers uses heat transfer plates fitted with gaskets that seal off each channel from the next and direct the fluids into alternate channels.

This type of plate heat exchanger is used throughout industry as standard equipment for efficient heating, cooling, heat recovery, condensation and evaporation.

Alfa Laval units have a reputation for:

- High thermal efficiency for effective heat transfer

- Compact design resulting in small quantities of materials used for heat transfer surfaces

- Low installation cost

- Easy dismantling and easy, rapid cleaning

- High performance with low hold-up volume

- Versatile, modular design

- Environmentally efficient

Click here for a Plate Heat Exchangers data sheet.

The range is continually being updated and extended to include new technical features and design innovations. The T series, for example, is built with a new frame design that paves the way for more distinct plate types per frame as well as opportunities for the use of modularized components. This ensures even easier and more rational assembly and service.

There is also a range of special wide-gap gasketed plate heat exchangers designed to cope with fluids that contain fibers and coarse particles. Units with wide-gap channels are also eminently suitable for use with highly viscous fluids.

For more information on specific models, click the links below.